Nissan X-Trail vs Honda CR-V 2025 | Reconditioned SUV in BD

November 28, 2025Nissan X Trail Price in Bangladesh

December 9, 2025How to Calculate CMT In The Garment Industry

Garment costing feels risky if I do not know the real cost of making each piece. One small mistake in CMT can cut profit, break trust with buyers, and damage long term business. Clear math solves that risk.

In this guide, I will walk through How to Calculate CMT In The Garment step by step. I will use simple examples, real factory logic, and the same thinking we use at GM Fashion as Bangladesh apparel manufacturers. By the end, you can read a tech pack, run a clean garment calculation, and set CMT charges that protect both buyer and factory.

CMT Meaning in Garment Manufacturing

CMT stands for Cut, Make, and Trim. This is a common model in the garment industry and the wider apparel manufacturing industry.

- Cut – fabric spreading and cutting in the garment unit

- Make – sewing operations, also called sewing manufacturing or stitching

- Trim – adding buttons, labels, zippers, hangtags, and other trims, then final checking

Under a pure CMT clothing model:

- The buyer sends fabric and most trims

- The factory focuses on garment production, labor, and basic overhead

- The buyer pays an agreed cost of making in garments, not the fabric cost

CMT is a core part of garment manufacturing, because this is the cleanest way to see the cost to cost garments for the making part only.

Role of CMT in the Apparel Industry and Manufacturing Cost

CMT connects the sewing floor to business profit. In the apparel industry, brands and apparel manufacturers use CMT in these ways:

- Builds the garment manufacturing cost base for each style

- Helps compare offers from different CMT manufacturers and clothing manufacturers

- Guides selling price, margin, and long term planning in the manufacturing industry

For the factory, CMT feeds into:

- Garment factory cost per style

- Full garment manufacturing unit cost

- Price discussion with buyers who work in the clothing industry worldwide

Strong CMT math gives control over:

- Real manufacturing cost

- Profit for each order

- Long term stability in the Bangladesh clothing industry and other markets

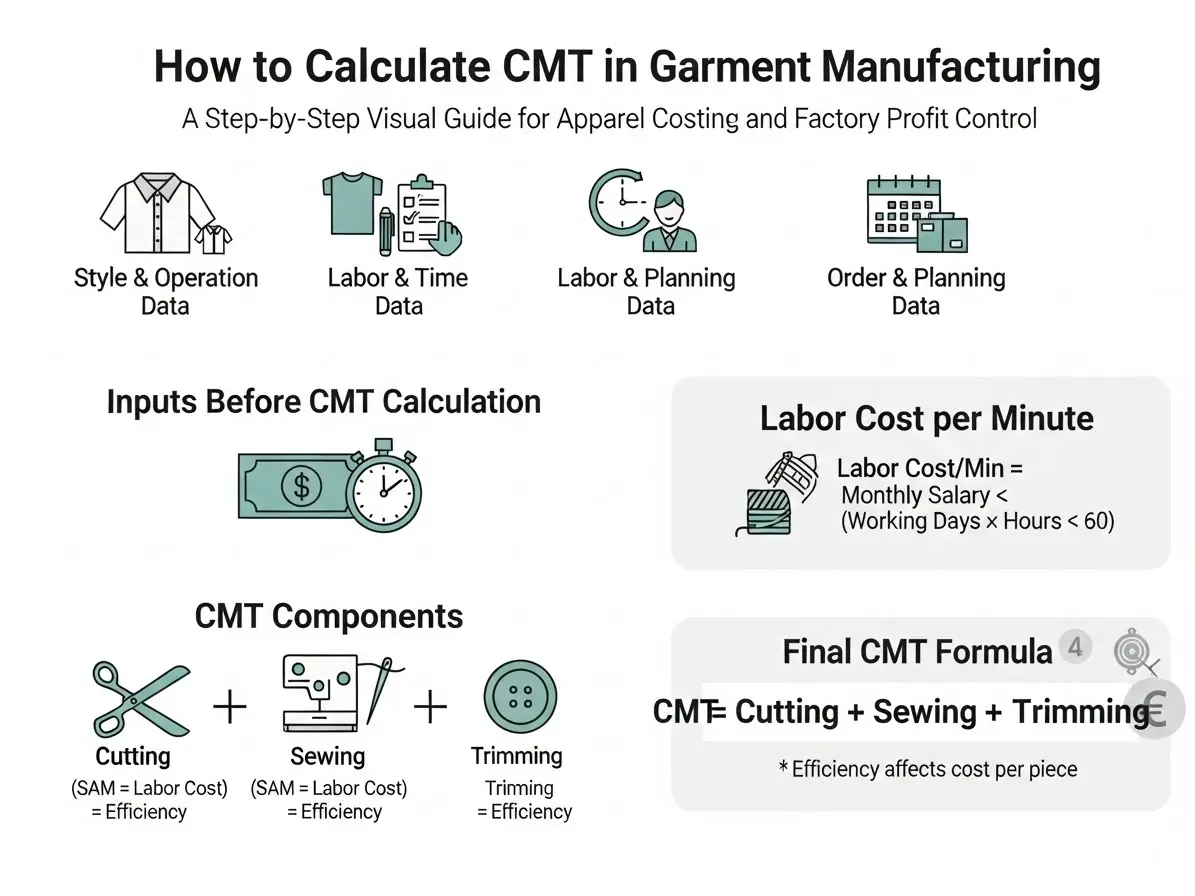

Inputs Needed Before Any Garment CMT Calculation

Clean input data makes clean CMT. Before I touch a calculator, I collect three groups of data.

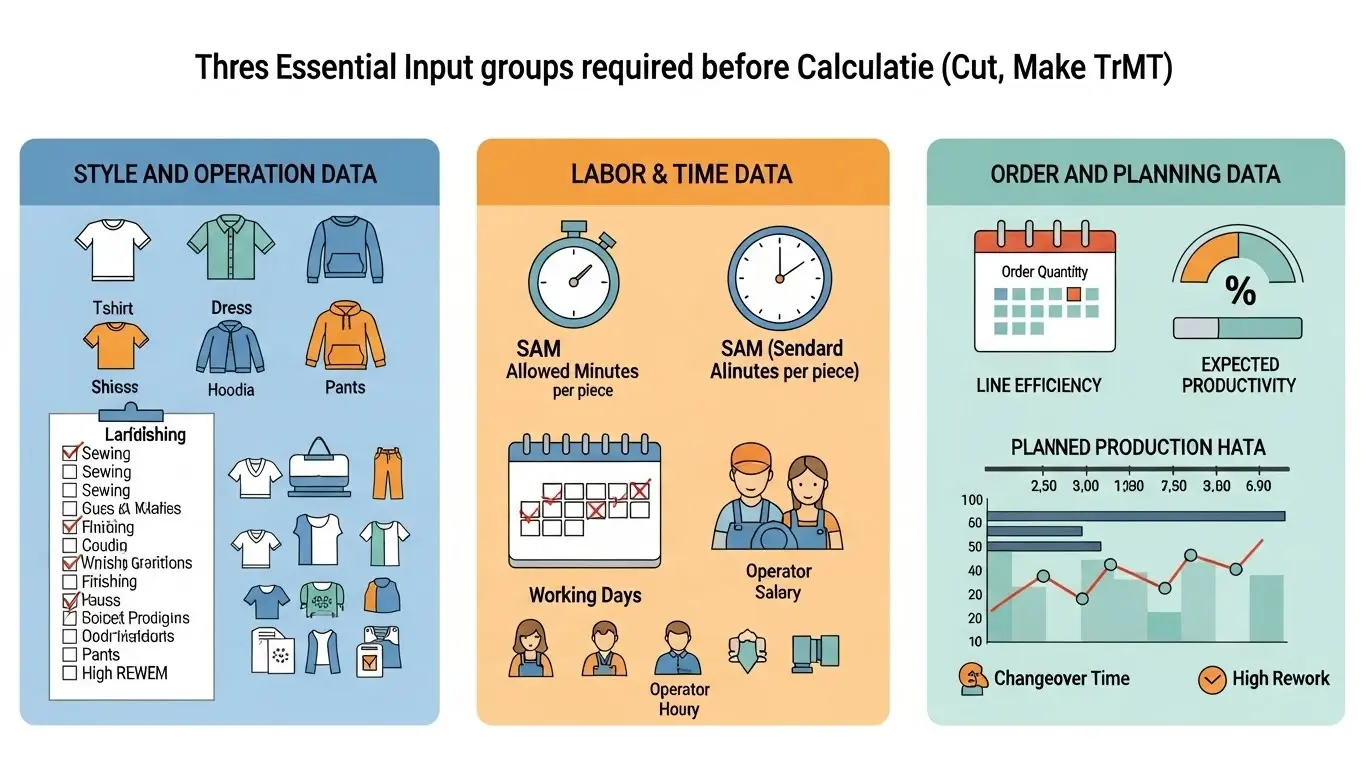

Style and Operation Data

Each style in garment manufacturing needs:

- Style type – t shirt, polo, dress, hoodie, pants

- List of operations for sewing manufacturing and finishing

- SAM or standard time for sewing and cutting, in minutes per piece

This data defines the labor content for that style, which links to CMT later.

Labor and Time Data

Next, I gather labor details for the line or garment unit:

- Average operator salary per month

- Number of working days in the month

- Working hours per day

- Total staff counted in that salary group

- Real line efficiency in garment production, not target efficiency

These numbers are needed for cost per minute calculation in garment industry.

Order and Planning Data

Good production planning and manufacturing planning also support CMT:

- Order quantity in pieces

- Planned hours for that style on each line

- Expected productivity calculation in garment industry reports for that style

- Extra time for changeover, samples, or high rework styles

With these three groups, I can move to the core math.

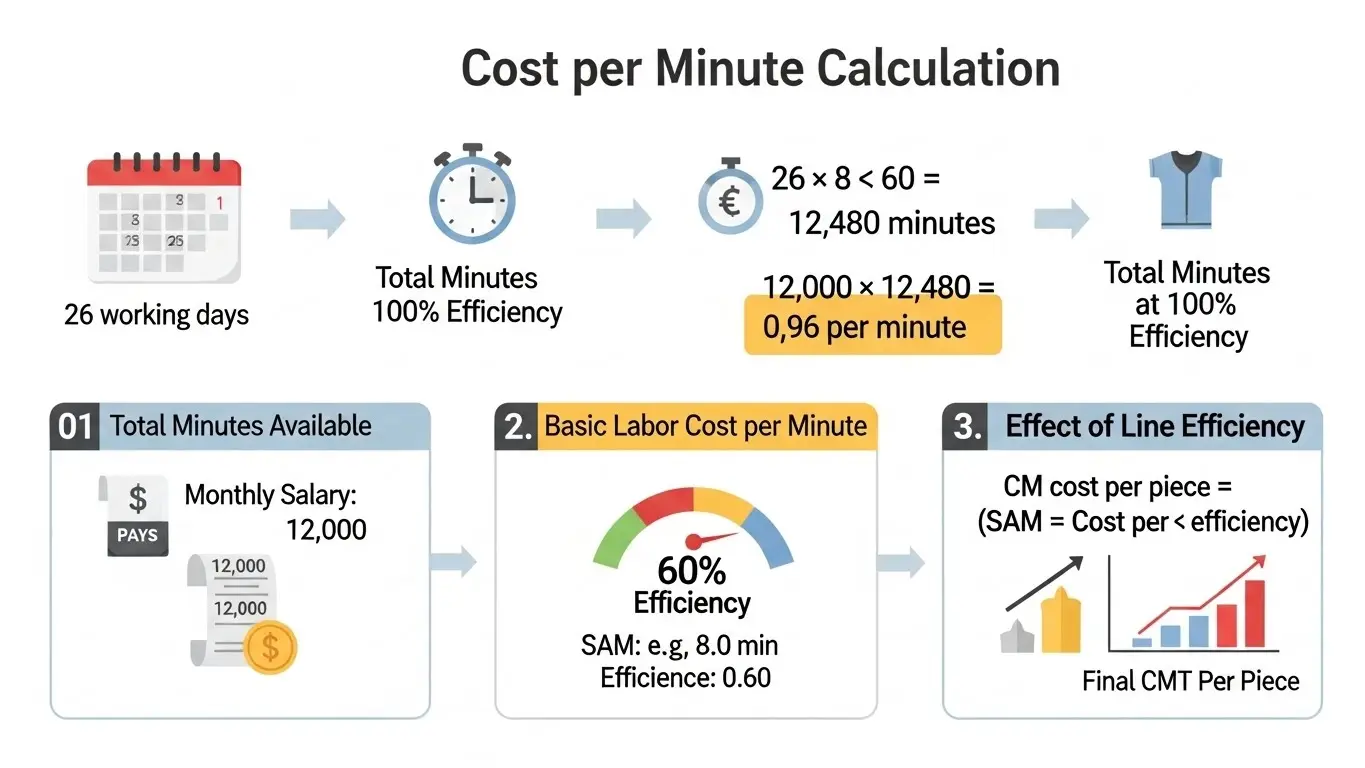

Cost per Minute Calculation in Garment Industry

CMT starts with the real cost for one minute of labor. This part often goes wrong in the apparel manufacturing industry, so I stay careful here.

Step 1 – Total Minutes Available

First, I find the total minutes a worker is present in a month.

Example:

- Working days per month – 26

- Working hours per day – 8

Total minutes per month:

26 days × 8 hours × 60 minutes

= 12,480 minutes

This gives the time at 100 percent efficiency.

Step 2 – Basic Labor Cost per Minute

Next, I divide the monthly salary by those minutes.

Example:

- Monthly salary – 12,000 currency units

Labor cost per minute at 100 percent

12,000 ÷ 12,480 ≈ 0.96 per minute

This is the base rate.

Step 3 – Effect of Line Efficiency

Real lines in industry and production rarely run at 100 percent output. Lower efficiency in manufacturing means fewer pieces per day, so each piece carries more labor cost.

A common CMT formula adjusts for efficiency like this:

CM cost per piece =

(SAM of garment × labor cost per minute) ÷ line efficiency

Line efficiency stays as a percent, for example 60 percent written as 0.60 in the formula.

This single step links:

- Cost per minute calculation in garment industry

- Actual garment CMT for each piece

Method To Calculate CMT in the Garment

A simple sentence answers the core question:

CMT per piece in garment manufacturing equals cutting cost plus sewing cost plus trimming cost, all based on real labor cost per minute and line efficiency.

Now I break it into clear steps.

Step 1 – Cutting Cost per Garment Unit

Cutting cost comes from:

- Cutting SAM in minutes per piece

- Labor cost per minute

- Cutting room efficiency

Formula:

Cutting cost per piece =

(Cutting SAM × labor cost per minute) ÷ cutting efficiency

This covers the labor in spreading, cutting, bundling, and ticketing for that style.

Step 2 – Sewing or Making Cost per Piece

Sewing or “Make” is the main part of clothing production.

Formula:

Sewing cost per piece =

(Sewing SAM × labor cost per minute) ÷ line efficiency

This includes all operators on the line, helpers, and basic direct sewing labor.

Step 3 – Trimming and Finishing Cost

Trimming cost covers:

- Time for attaching buttons, labels, zippers, and other trims

- Time for loose thread cutting, basic checking, and packing if part of CMT

Formula can follow the same idea:

Trimming cost per piece =

(Trimming SAM × labor cost per minute) ÷ trim line efficiency

In many factories, the merchandiser sets a fixed trim and finishing cost based on past garment production data. That is fine as long as it comes from real time studies.

Step 4 – Total CMT Cost per Piece

Full CMT per piece:

CMT per piece =

Cutting cost + Sewing cost + Trimming cost

This number is the cost of making in garments. Once I know it, I can build the full garment manufacturing unit cost and see the margin on any style.

Worked Example of CMT Calculation for a Knit Top

A simple knit top example makes this clear. Values here are only for learning.

Assume:

- Style – basic crew neck knit top

- Order quantity – 3,000 pieces

- Operator monthly salary – 12,000 taka

- Working days – 26

- Hours per day – 8

- Line efficiency – 60 percent

- Sewing SAM – 8 minutes

- Cutting SAM – 5 minutes

- Trimming and finishing value – 3 taka per piece based on past data

Step 1 – Labor Cost per Minute

Total minutes:

26 × 8 × 60 = 12,480 minutes

Labor cost per minute at 100 percent:

12,000 ÷ 12,480 ≈ 0.96 taka per minute

Step 2 – Cutting Cost

Formula:

Cutting cost = (Cutting SAM × labor cost per minute) ÷ efficiency

Cutting cost = (5 × 0.96) ÷ 0.60

= 4.8 ÷ 0.60

= 8 taka per piece

Step 3 – Sewing Cost

Sewing cost = (8 × 0.96) ÷ 0.60

= 7.68 ÷ 0.60

≈ 12.8 taka per piece

Step 4 – Trimming Cost

Given fixed:

Trimming cost = 3 taka per piece

Step 5 – Total CMT per Piece

CMT charges =

8 + 12.8 + 3

= 23.8 taka per piece

If the buyer pays in dollars, I can divide by the current exchange rate to get CMT in USD.

This simple set of clear steps gives a strong base for price discussion with buyers and protects margin in the garment manufacturing floor.

CMT Versus Full Garment Manufacturing Cost

Many people mix CMT with full garment manufacturing cost, but the two are not the same.

CMT as Cost of Making Only

CMT covers:

- Cut – fabric cutting labor and basic overhead in that area

- Make – sewing line labor, helpers, quality staff on the line

- Trim – trim attaching labor and basic finishing

In a pure CMT model:

- The buyer provides fabric and most trims

- The factory acts as a CMT manufacturer and earns through CMT charges only

Full Garment Manufacturing Cost

Full manufacturing cost goes beyond CMT and adds:

- Fabric cost per piece

- Trim and accessory cost per piece

- Printing, embroidery, wash, or other value add

- Extra finishing cost, testing, and quality control

- Factory overhead and admin

- Finance, transport, and other indirect costs

Apparel clothing manufacturers who handle full service must manage both parts:

- CMT

- All these extra cost heads

When Each Model Makes Sense

Buyers often choose:

- CMT model with CMT manufacturers when they want to control fabric and trims directly

- Full manufacturing model with clothing manufacturers when they want a one stop partner for fabric, trims, and garment manufacturing

Both models sit inside the same garment industry, but the price logic changes.

Link Between CMT, Planning, and Line Productivity

CMT is not only a math exercise. Clear CMT supports real production planning and manufacturing planning on the floor.

Use of CMT in Daily Planning

Planning and IE teams can:

- Use SAM and CMT to set daily production targets per garment unit

- Assign the right style to the right line based on skill and efficiency in manufacturing

- Predict garment factory cost behavior for each style mix

Impact on Productivity Calculation in Garment Industry

Higher productivity in garment production gives:

- More pieces per day for the same salary base

- Lower CMT per piece

- Better room for fair price and healthy margin

Productivity calculation in garment industry reports show:

- Actual minutes produced per day

- Gap between plan and reality

- Actions that can reduce CMT next month

Effect on Cost to Cost Garments

A stable and efficient line directly lowers:

- Cost to cost garments

- Price pressure for the buyer

- Risk for the factory

For this reason, I connect CMT reviews with line performance reviews, not only with costing sheets in the office.

Common CMT Calculation Mistakes That Hurt Profit

A few simple errors can damage CMT accuracy. I watch for these in every garment manufacturing project.

- Use of 100 percent efficiency in formulas while actual efficiency is lower

- Use of old SAM values that do not match the current method or machine layout

- Ignoring rework and repair time for complex styles

- Forgetting time for line set up and first bulk in each garment unit

- Copying CMT from another style without checking operations and trim count

Each of these mistakes pushes real garment manufacturing cost higher than the CMT in the sheet. That gap eats profit and creates tension with buyers.

CMT in the Bangladesh Clothing Industry and GM Fashion Practice

The Bangladesh clothing industry has a strong place in global garment manufacturing. Many brands trust Bangladesh apparel manufacturers for knit, woven, and activewear.

At GM Fashion, I use CMT as a daily control tool, not only as a number in a quote.

How We Handle CMT at GM Fashion

In our factory:

- Each new style gets a fresh garment calculation with updated SAM

- Real line data feeds our productivity calculation in garment industry reports

- CMT for garment CMT work stays linked to order size, fabric type, and trim complexity

This method keeps garment factory cost under control while we protect quality.

Why Clear CMT Helps Our Buyers

Brand teams that work with us gain:

- Clear and honest CMT charges for each style

- Stable prices over seasons when industry and production costs change slowly

- Realistic delivery plans based on actual production planning and capacity

This mix makes us more than simple clothing manufacturers. We act as a stable partner in the full apparel manufacturing industry.

Quick Reference – CMT Formula and Key Terms

Short list for quick review during costing work.

- Labor cost per minute

- Monthly salary ÷ total minutes in the month

- Monthly salary ÷ total minutes in the month

- CM cost per piece

- (Garment SAM × labor cost per minute) ÷ line efficiency

- (Garment SAM × labor cost per minute) ÷ line efficiency

- CMT per piece

- Cutting cost + Sewing cost + Trimming cost

- Cutting cost + Sewing cost + Trimming cost

- CMT

- Cut, Make, and Trim, cost of making part only

- Cut, Make, and Trim, cost of making part only

- SAM

- Standard allowed minutes to make one piece

- Standard allowed minutes to make one piece

- Line efficiency

- Output minutes ÷ input minutes, in percent

- Output minutes ÷ input minutes, in percent

These small blocks help keep garment calculation logic steady across styles.

Short FAQ on CMT and Garment Manufacturing Cost

People often ask: how to calculate CMT per piece in a simple way?

I use a four step path, find labor cost per minute, calculate cutting, sewing, and trimming cost, then add them to get CMT per piece.

People often ask: what CMT means in apparel cost?

CMT stands for cut, make, and trim, and covers the making side of clothing production without fabric cost in a pure CMT model.

People often ask: why line efficiency changes CMT charges so much?

Low efficiency means fewer pieces per day for the same salary, so each piece carries more labor cost and CMT goes up.

People often ask: whether CMT equals full garment cost.

CMT covers only making, while full cost includes fabric, trims, value add, tests, and full manufacturing cost items.

People often ask: how clothing manufacturers can reduce garment CMT.

Better work methods, smart manufacturing planning, skill training, and strong quality at source raise efficiency and bring CMT down.

Partner With GM Fashion for Safe CMT and Reliable Garment Manufacturing

Strong CMT math turns into strong business. Clear numbers protect your price, your margin, and your brand image with shoppers.

As a trusted name among clothing manufacturers and apparel manufacturers in Bangladesh, we at GM Fashion use this same CMT logic daily in our garment manufacturing lines for casual wear, formal wear, and activewear.

Brand teams that want a stable partner can work with us under both models:

- Pure CMT work with clean CMT charges

- Full garment manufacturing unit cost service with fabric and trims

For buyers who plan new programs with a reliable partner in Bangladesh, Clothing Manufacturers in Bangladesh – GM Fashion stands ready to support your next style, from clear CMT math to on time bulk shipment.

Send your tech pack or costing sheet, and I will help you apply this CMT method to your style so you can quote with confidence and grow safely in the global apparel industry.